Learn 3D Modeling PDF Course (3 Volumes, 600+ Pages)

➔🇫🇷 version

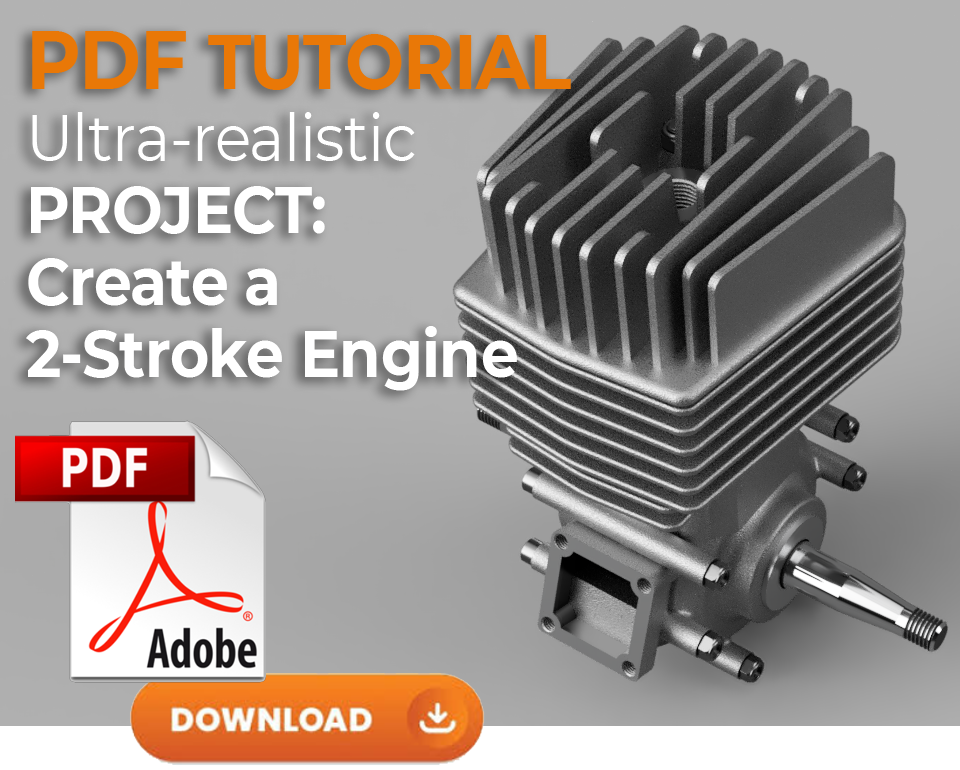

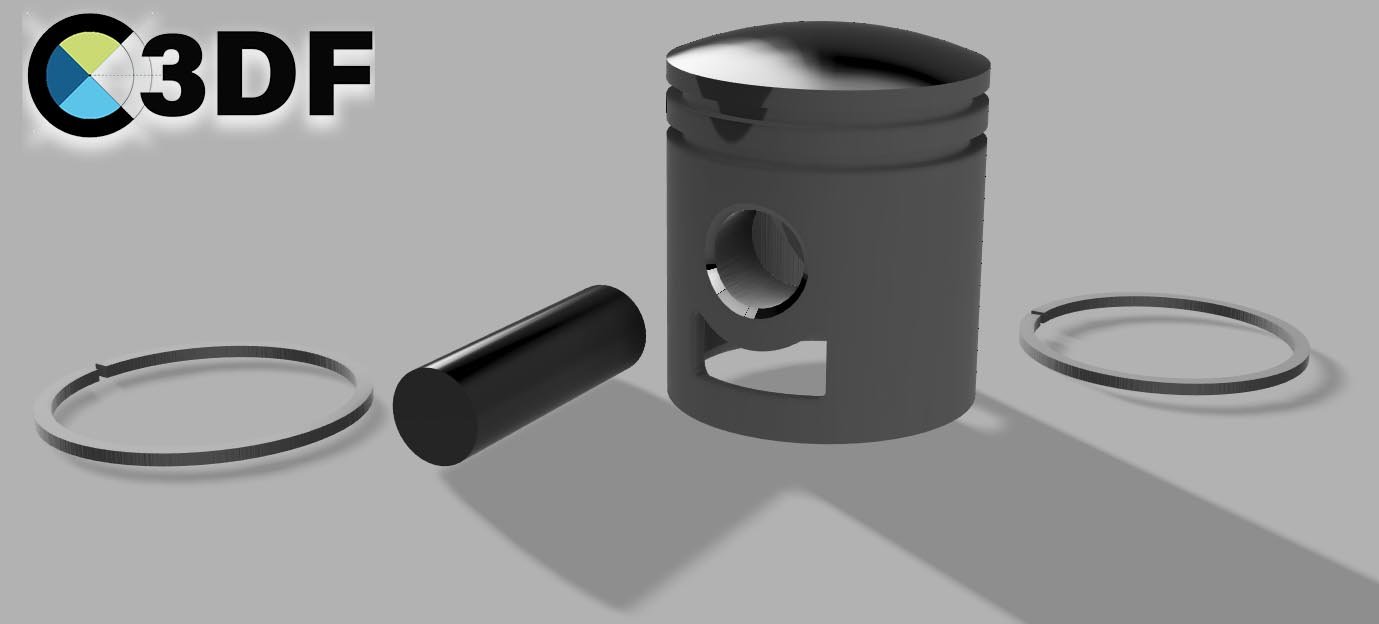

Discover our exclusive training (in PDF Tutorial format) in 3 Volumes, dedicated to the complete 2-stroke engine modeling with Fusion 360.

This course is specifically designed for CAD enthusiasts looking to enhance their 3D modeling skills. Accessible in PDF on formation-fusion-360, this training offers a progressive and structured learning approach.

It covers in detail the creation and assembly of the essential parts of a 2-stroke engine, starting from basic displacement data. Master all the steps, from sketching to assembly, and turn your passion for modeling into practical skills.

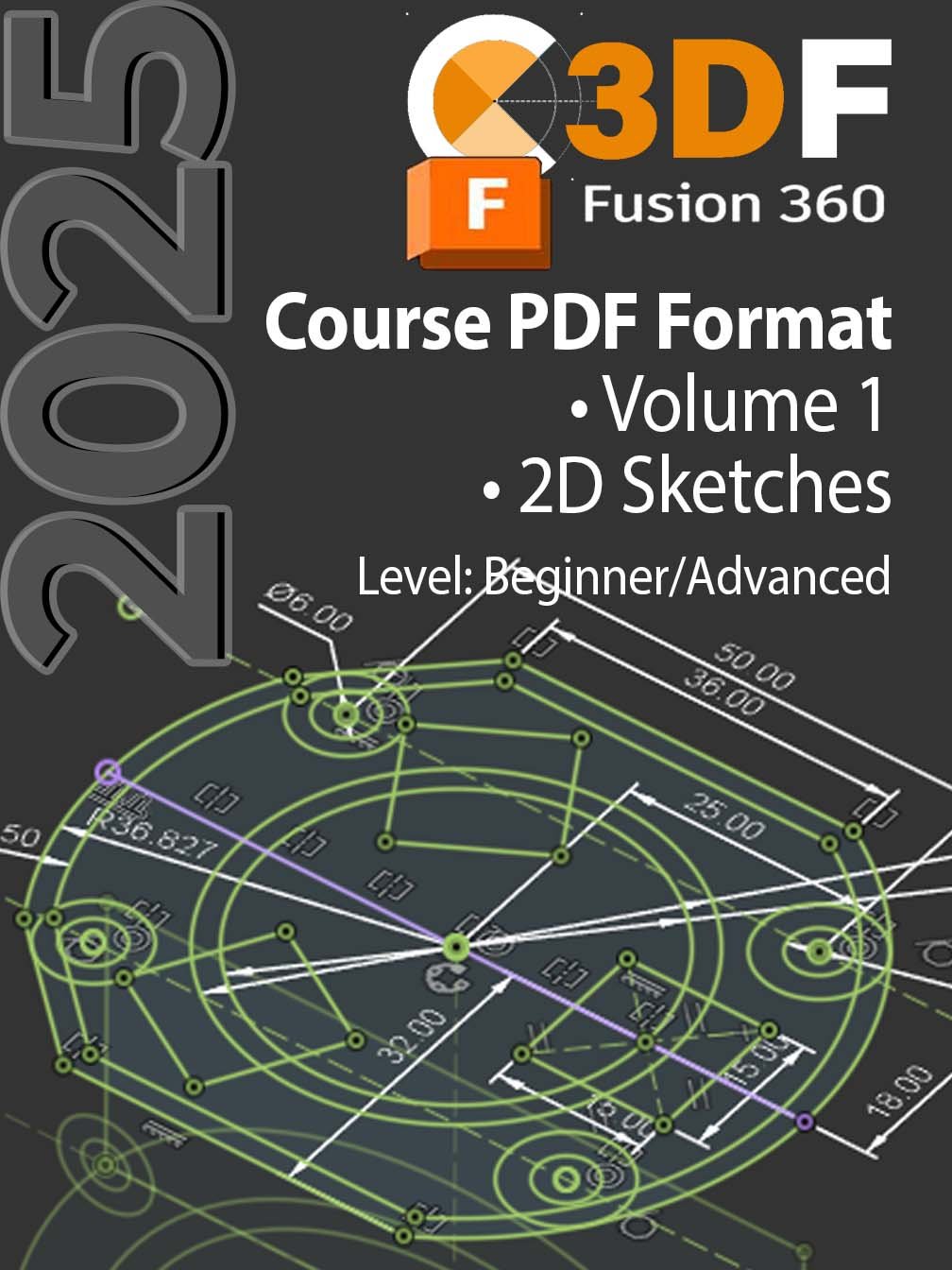

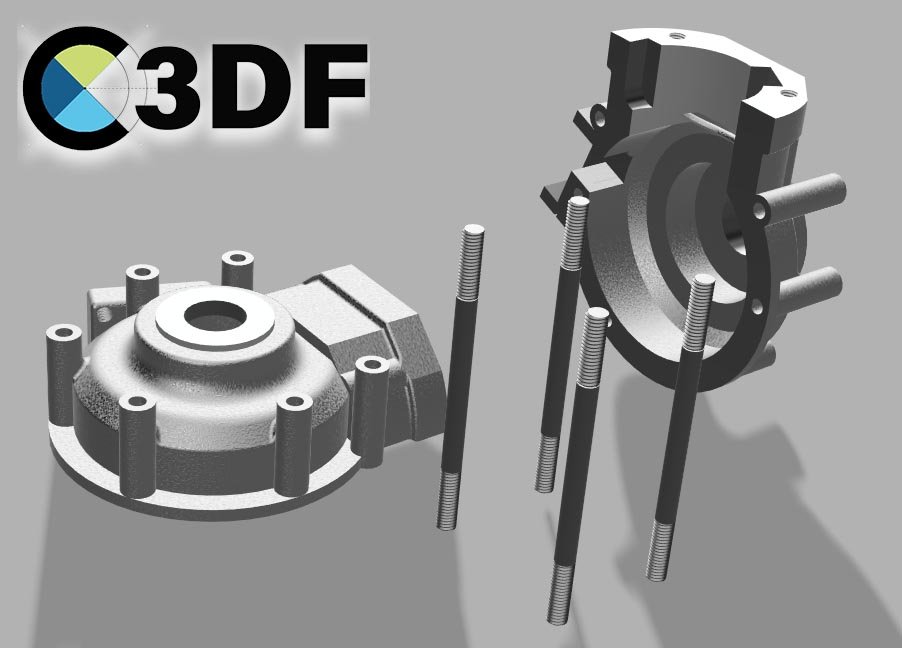

VOLUME 1 2-Stroke Engine Fusion 360

Draw the 2D Sketches of the Project

In the first volume, we dive into the creation of 2D sketches for each essential component of the 2-stroke engine. This volume is crucial for laying the foundation of your modeling, as a well-designed sketch is key to a successful assembly.

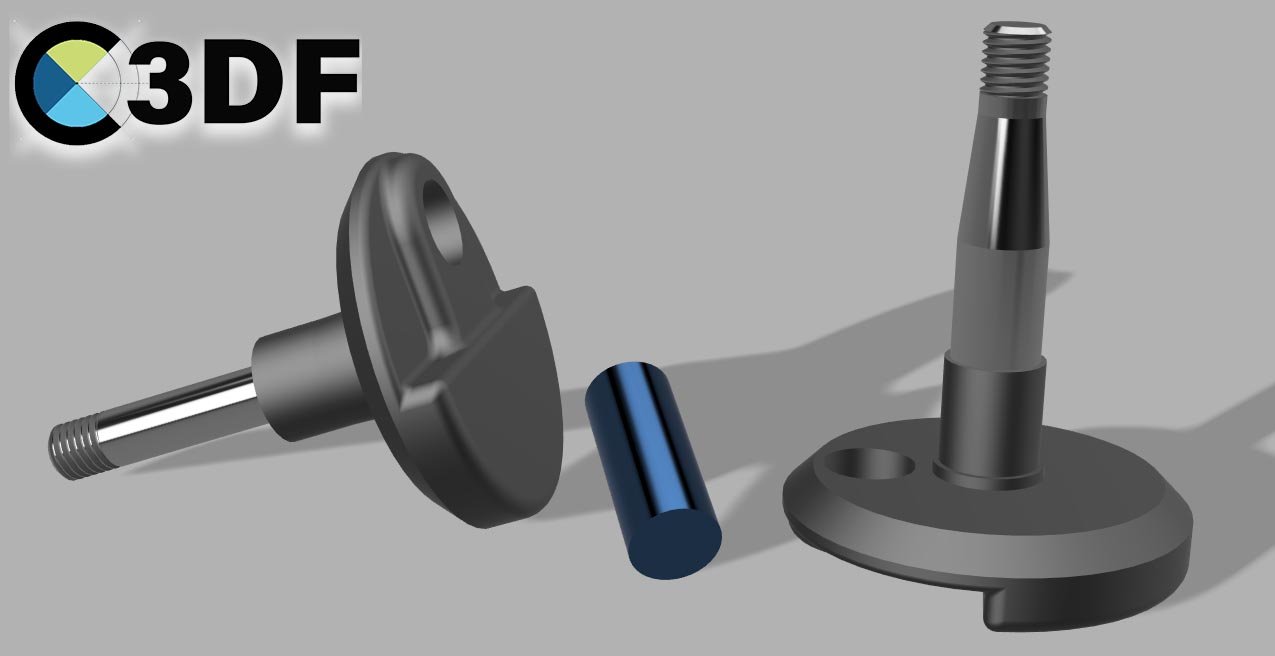

We model key parts such as the piston, rings, shafts, bearings (Fusion 360 library), connecting rod, crankshaft, the two half-casings, cylinder, liner, seals, and cylinder head. Using the displacement measurements as a basis, we will draw the precise contours of each element in 2D.

To do this, we use the classic drawing tools available in Fusion 360. Among these tools, you will learn to use lines, arcs, circles, and polygons to create complex geometric shapes. Each tool has its specifics, and we will show you how to apply them to design parts that meet the exact specifications of your engine. You can independently order Volume 1, 2, 3, or (the complete 3-Volume pack).

The focus is on how to effectively use sketches in Fusion 360.

You will learn how to:

- Set up your workspace: Choose the appropriate drawing plane and define the initial dimensions to ensure the accuracy of your sketch.

- Use geometric constraints: Apply constraints to maintain the relationship between different sketch entities, ensuring a consistent and adaptable design.

- Dimension your sketches: Add dimensions to specify the exact measurements of each part, which is crucial for the final assembly. We will also cover how and why to fully constrain our 2D sketches.

- Use the mirror tool: Create symmetrical sketches efficiently, thus reducing design time for parts like the crankshaft or the casings.

At the end of this volume, you will have all the necessary 2D sketches to move on to 3D modeling, preparing you to transform your concepts into solid models ready to be assembled. This volume is essential for anyone who wants to master 3D modeling in Fusion 360, starting with a solid foundation in 2D sketches. This part is a critical step in the 2-stroke engine project.

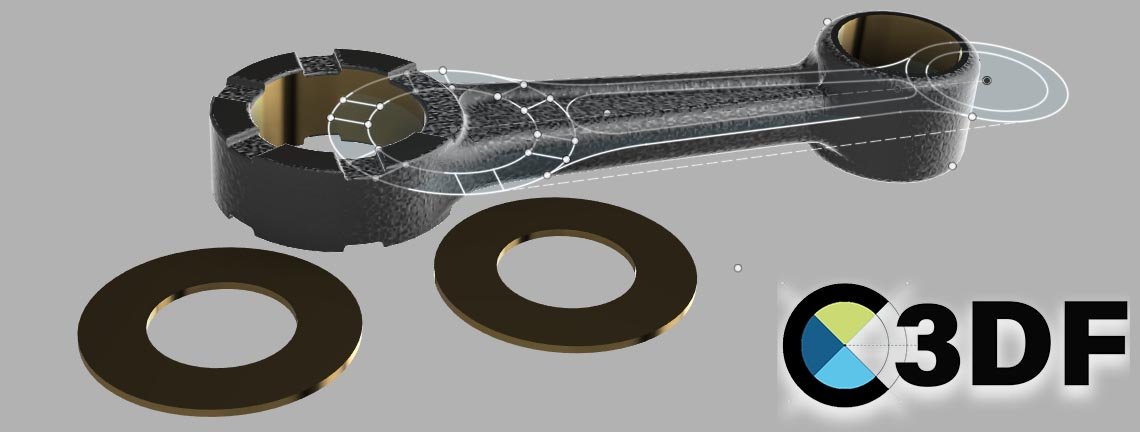

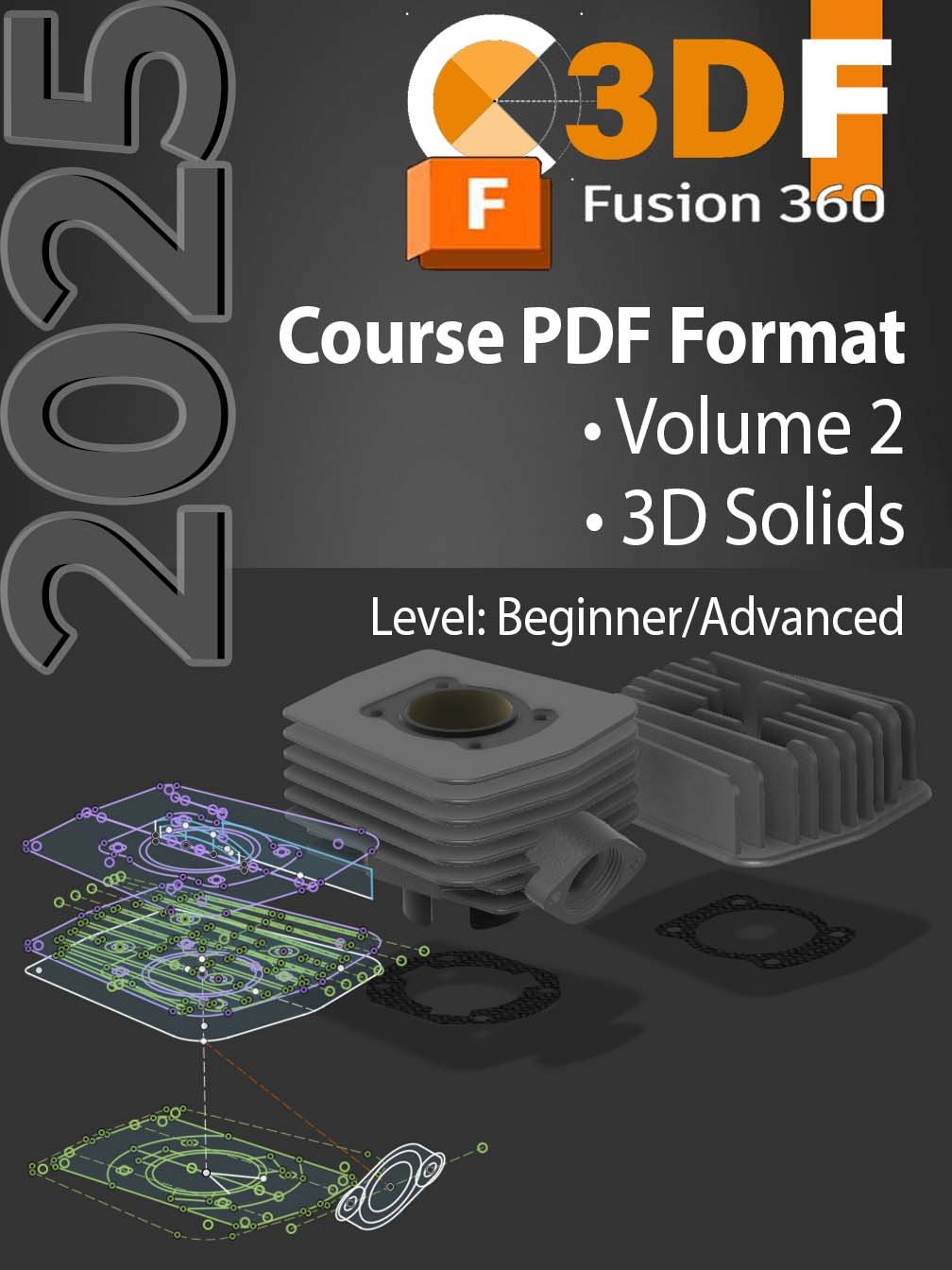

VOLUME 2 2-Stroke Engine Fusion 360

Modeling the 3D Solids of the Project from the Sketches

In this second volume, we focus on converting the 2D sketches into 3D solid models, a crucial step in the modeling process. This transition is essential to bringing your designs to life, as it allows you to visualize each part in its entirety, ready to be assembled. Each part of the 2-stroke engine that you previously sketched will be transformed into a complete, functional solid object.

We will start by importing the 2D sketches you created in the previous volume, guiding you through a series of detailed and illustrated instructions for each component. You will learn how to select and prepare your sketches for modeling, checking the accuracy of dimensions and contours to ensure a flawless conversion.

For those who want to jump straight into Volume 2 (without going through Volume 1, which covers the sketches), you will have the option to download the 2D sketches at the start of Volume 2. Follow this link to order your 2-Stroke Engine Project PDF Tutorial now.

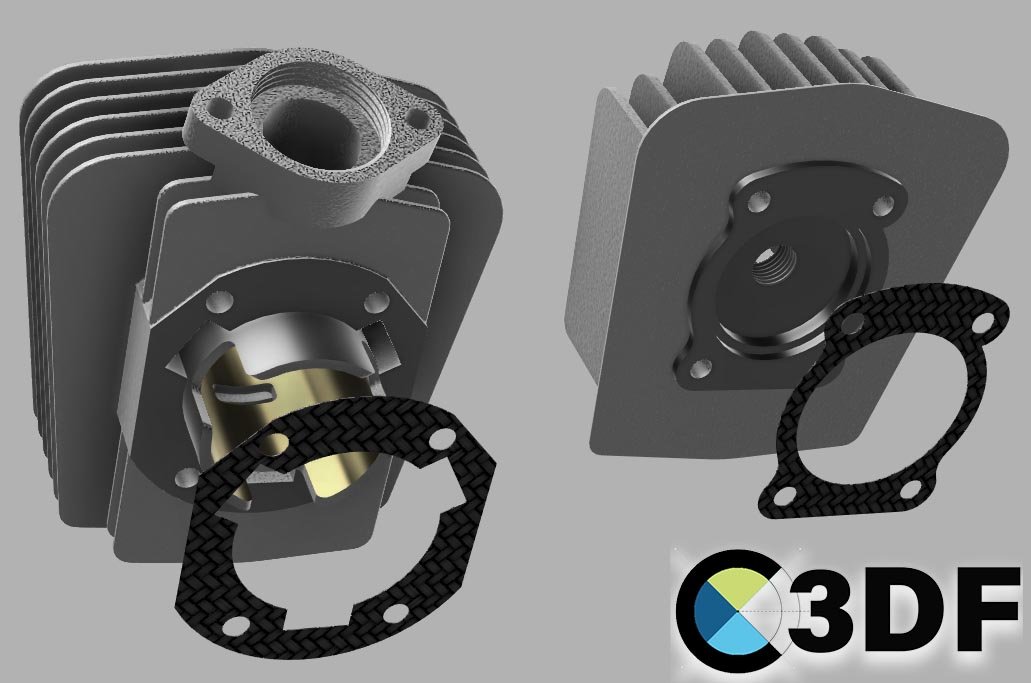

We will explore various modeling techniques available in Fusion 360.

Among them, you will learn how to use:

- Extrusion: To add depth to your sketches and create solid shapes from your 2D contours. You will learn how to adjust the extrusion parameters to achieve the exact dimensions for each part, whether it’s the piston, the cases, or the cylinder.

- Revolution: This technique allows you to create symmetrical shapes, such as the segments or the crankshaft, by rotating a sketch around an axis. We will show you how to set the revolution axis to optimize your design.

- Part Assembly: You will learn how to use assembly tools to define the relationships between different parts, ensuring that each element fits perfectly with the others. Concepts such as joints, positioning constraints, and dimensional adjustments will be covered.

- Creation Operations: We will guide you through advanced operations like cutting, hollowing, and chamfering, in order to refine your models and add functional details, such as grooves for seals and contact surfaces for bearings.

As you progress, you will also learn how to manage the essential geometric tolerances for optimal fit during the final assembly.

We will show you how to check intersections between parts and how to use visualization tools to test the functionality of your design before finalizing your model.

At the end of this volume, you will have mastered the 3D modeling tools in Fusion 360, enabling you to create solid parts ready for assembly, thereby laying the foundation for a successful mechanical modeling project. You will then be prepared to move on to the final step: the complete assembly of your 2-stroke engine.

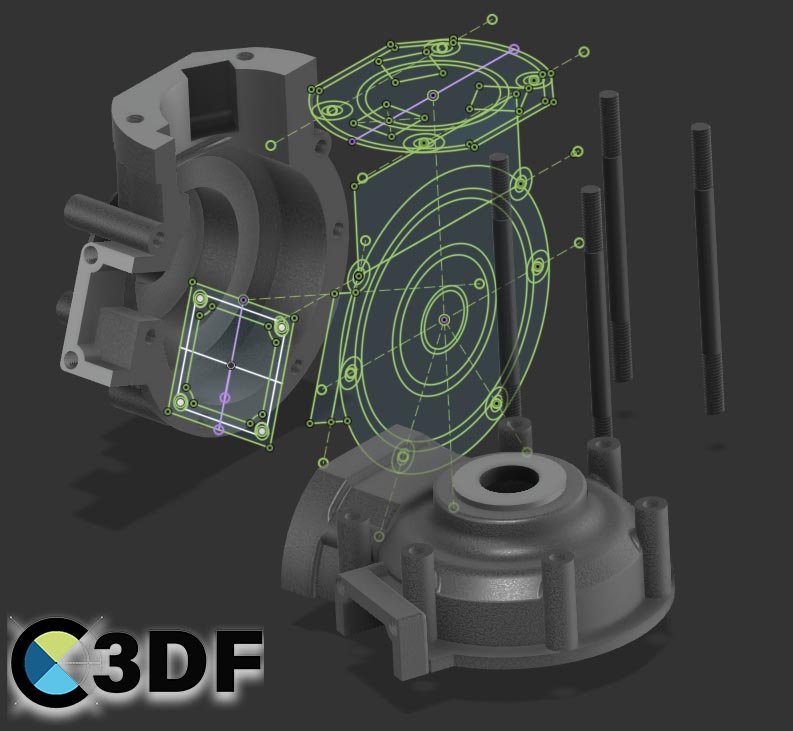

VOLUME 3 2-Stroke Engine Fusion 360

Assemble the Project with Functional Constraints

In this third and final volume, we guide you through the process of assembling the various parts of the 2-stroke engine that you have modeled. Assembly is a crucial step, as it not only ensures the coherence of your design but also simulates the engine’s functionality under real-world conditions.

This phase of synthesis is essential to make sure each part fits perfectly and operates smoothly within the whole.

This volume focuses on applying the necessary mechanical constraints to ensure realistic and smooth operation of the parts. You will first learn how to assemble the components by importing your solid models into a new assembly space.

Organize, Simulate, Optimize: Master the 2-Stroke Engine Assembly in Fusion 360!

In this third and final volume, we guide you through the assembly process of the various parts of the 2-stroke engine. Assembly is a crucial step that not only allows you to check the consistency of your design but also simulates the engine’s performance under real-world conditions.

This synthesis stage is essential to ensure that each part fits together perfectly and functions smoothly within the whole assembly.

This volume focuses on applying the necessary mechanical constraints to guarantee a realistic and smooth operation of the parts. You will first learn to assemble the components by importing your solid models into a new assembly workspace.

You will discover how to organize your parts for clear and efficient visualization, emphasizing the method of adding components. Using intuitive tools, you will position each part correctly, ensuring that your 2-stroke engine is optimally configured before moving on to the next stage.

Once your parts are in place, you will learn how to apply functional constraints using the different options available in Fusion 360. These constraints, including coincidence, contact, and distance relationships, are essential for simulating the interactions between components. You will define constraints that faithfully reflect real-world mechanical relationships, ensuring that each part functions as expected and preventing potential malfunctions.

After applying the constraints, you will be able to visualize the engine in action. We will show you how to use the simulation tool to test the movement of the parts, allowing you to identify any conflicts or assembly issues. This step is vital for validating the mechanical operation of the 2-stroke engine before any production or 3D printing. You will learn to analyze the engine’s dynamic behavior, helping you detect and fix potential errors.

Next, you will learn how to conduct simple analyses to evaluate your engine’s performance. This includes checking movement efficiency, potential friction, and the stresses on parts under load. These analyses will help you understand how to optimize your design to make it even more functional. You will develop a critical approach to the performance of your assemblies, gaining skills that will be useful for future projects.

By the end of this volume, you will have a complete model of your 2-stroke engine, fully assembled and functional. This assembly process, combined with motion simulation, will give you a deep understanding of the interactions between mechanical components, as well as practical skills for your future 3D modeling projects. You will then be ready to apply these skills to other projects, using Fusion 360 to design complex and innovative systems in the mechanical field, further strengthening your expertise in 3D modeling.

Conclusion: Master 3D Modeling of a 2-Stroke Engine with Fusion 360 in PDF Format

In conclusion, our three-volume course on 3D modeling of a 2-stroke engine with Fusion 360 provides you with a structured and comprehensive approach to mastering computer-aided design. From drawing 2D sketches to creating solid models, through to assembly and applying functional constraints, each step is designed to equip you with the skills needed to efficiently and precisely execute mechanical projects.

This training, available in PDF format on formation-fusion-360, is ideal for CAD enthusiasts eager to refine their skills and gain practical expertise in 3D modeling. By following these three volumes, you will be able to design, model, and simulate complex systems while developing a deep understanding of mechanical interactions.

Moreover, this training is offered by C3DF, a professional training organization for adults, led by a mechanical engineering instructor. Thanks to its expertise and pedagogical approach, C3DF (c3df.fr / i3df.fr) guarantees a high-quality learning experience tailored to your needs and pace.

Don’t wait any longer to turn your ideas into reality and discover how our training can help you excel in 3D modeling with Fusion 360!